Services

Pro-Mech Engineering offers products and services complying with our client’s requirement, specifications, quality standards, and international codes & standards. We specialize in providing engineering solutions to various problems found onsite during plant operation, regular maintenance and plant shutdowns, which has helped our clients not just reduce their maintenance costs but also improve equipment performance with reduced downtime.

Mechanical Design Engineering

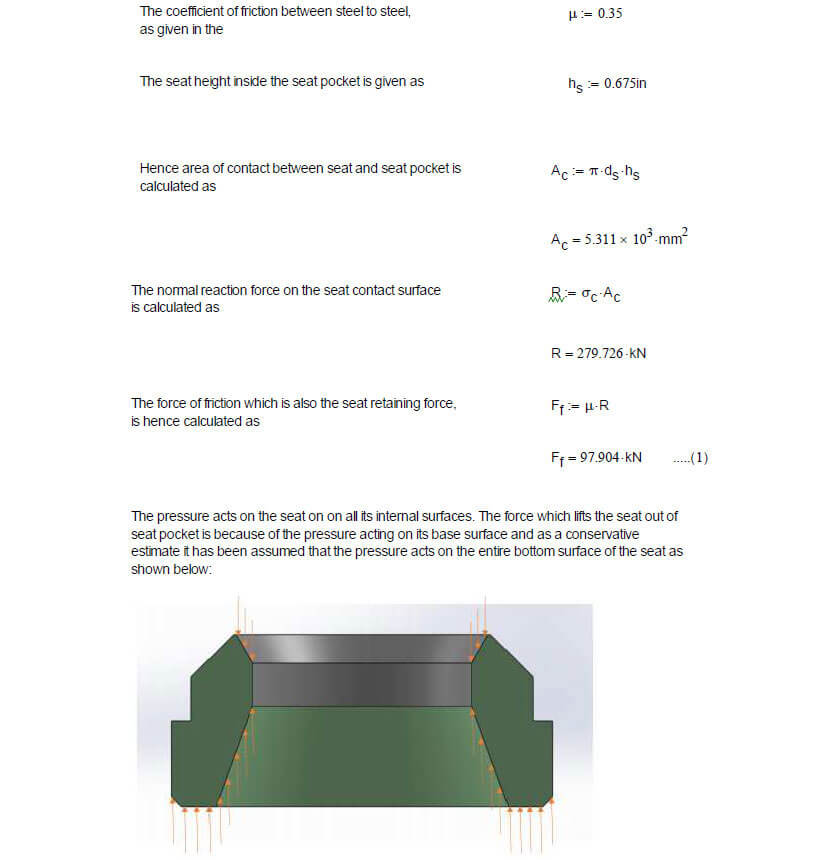

We strive to achieve optimum equipment performance to improve reliability and reduce maintenance costs. We study the process conditions, equipment sizing and selection to provide engineering design solutions when there are repeated and undesirable equipment failures.

We also provide complete design solutions for actuated valves including mounting bridge, drive adaptor & extended bonnet design with calculations & drawings.

Our engineering services conform to all international codes and standards such as ASME, AS/NZ, API, ISO and client specifications.

Materials Engineering

Our knowledge of materials, heat treatment processes and hard-facings etc., and their application under various process conditions such as corrosive service, erosive steam conditions and severe service conditions has helped our clients improve the service life of their equipment, reduce down-time and maintenance costs.

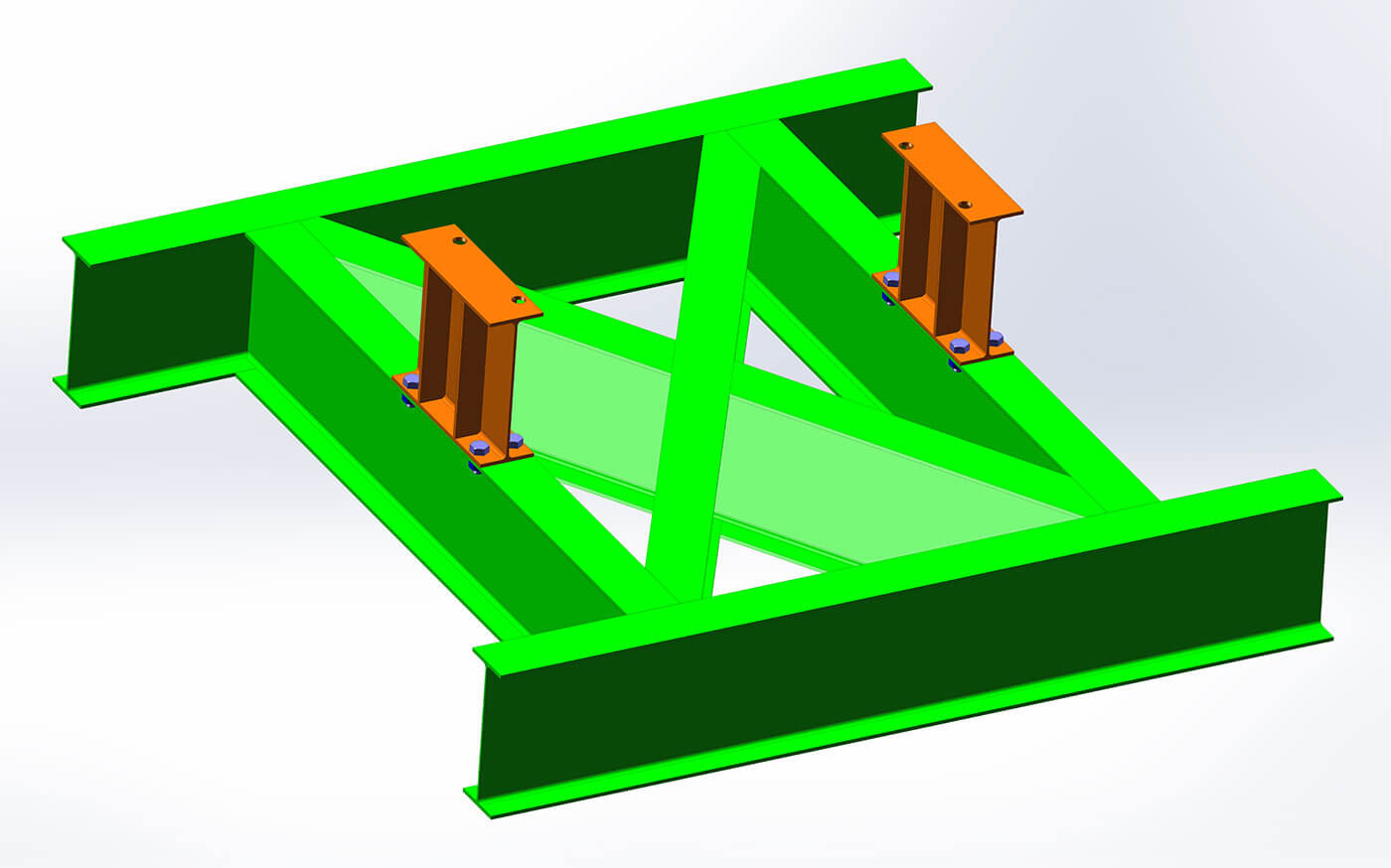

Jigs & Fixture Design

Safety comes first in all of our projects. In order to safely carry out maintenance works, a reliable jig, fixture or a mounting frame is often needed to meet the specific challenges related to the job and mitigate any risks. We have experience in design and supply of specific fixtures and mounting frames which complement the safe work or maintenance procedures.

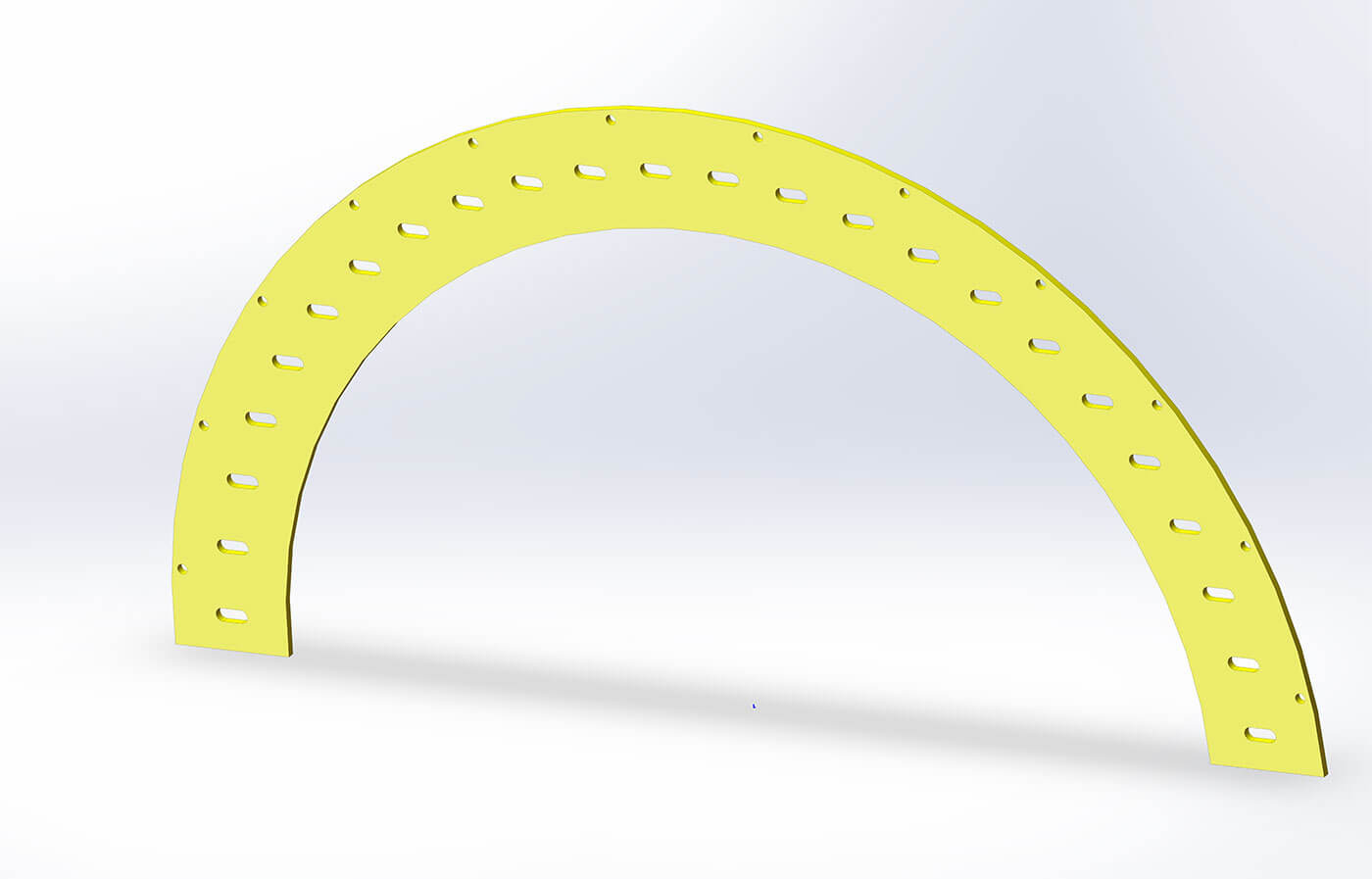

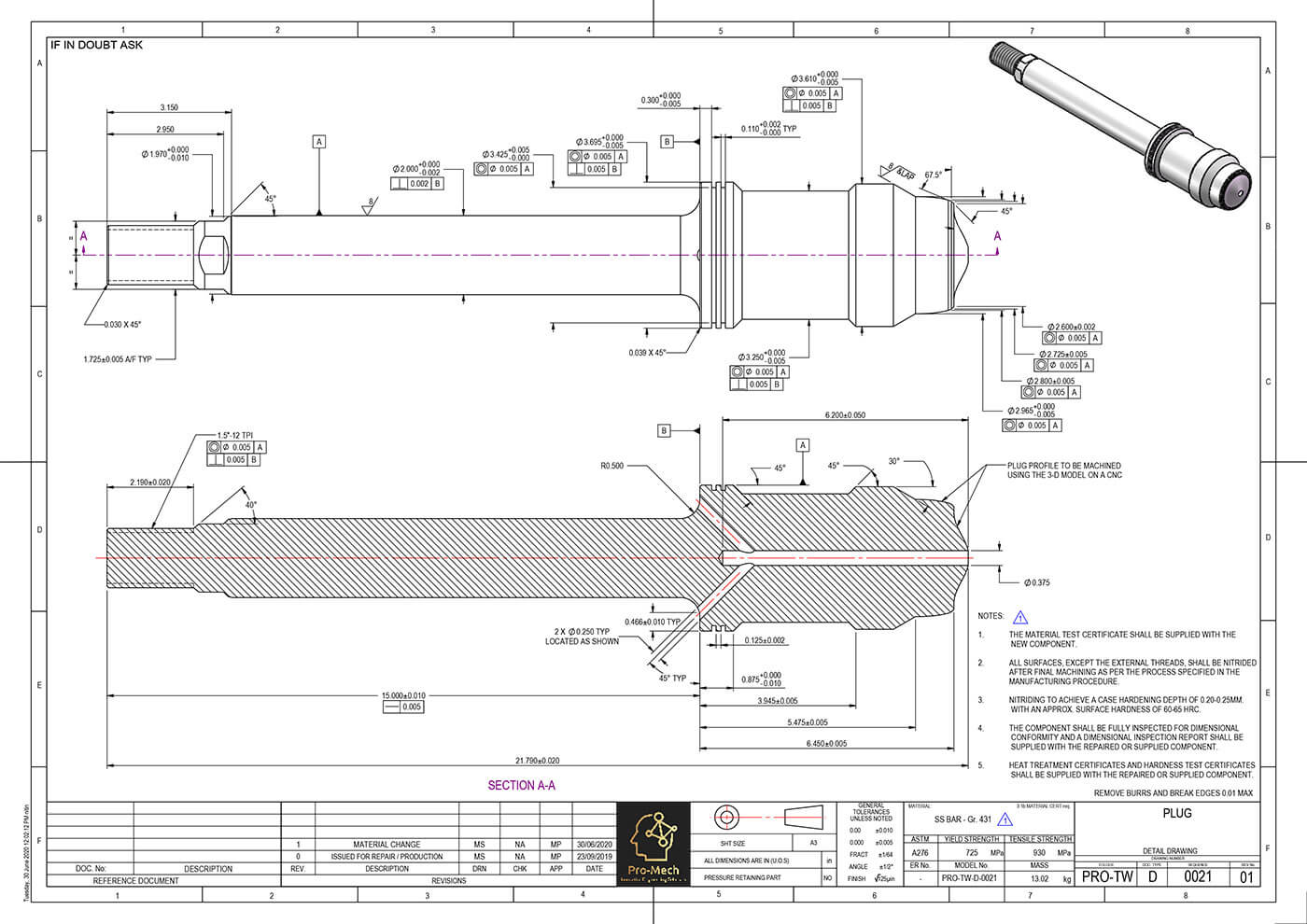

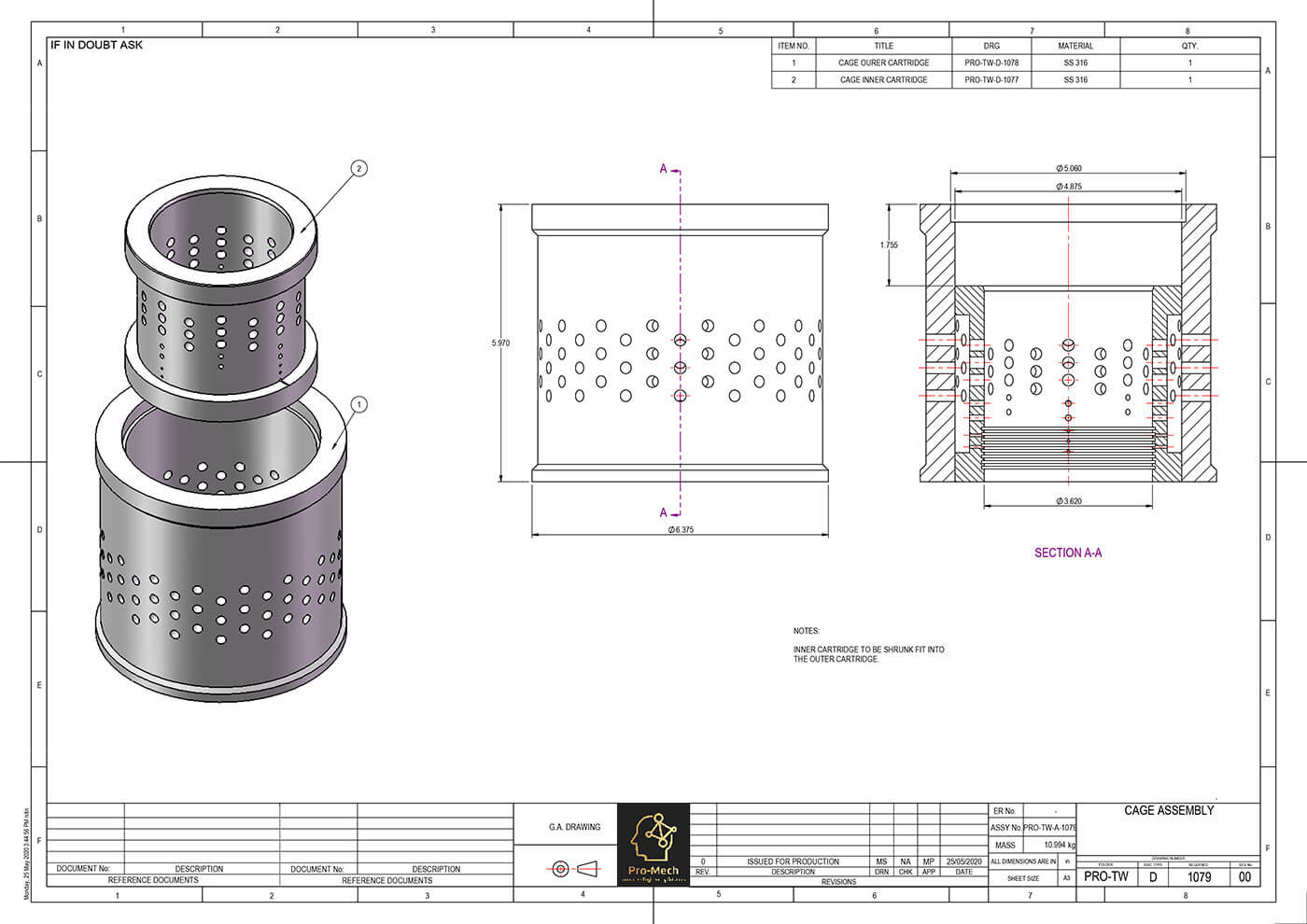

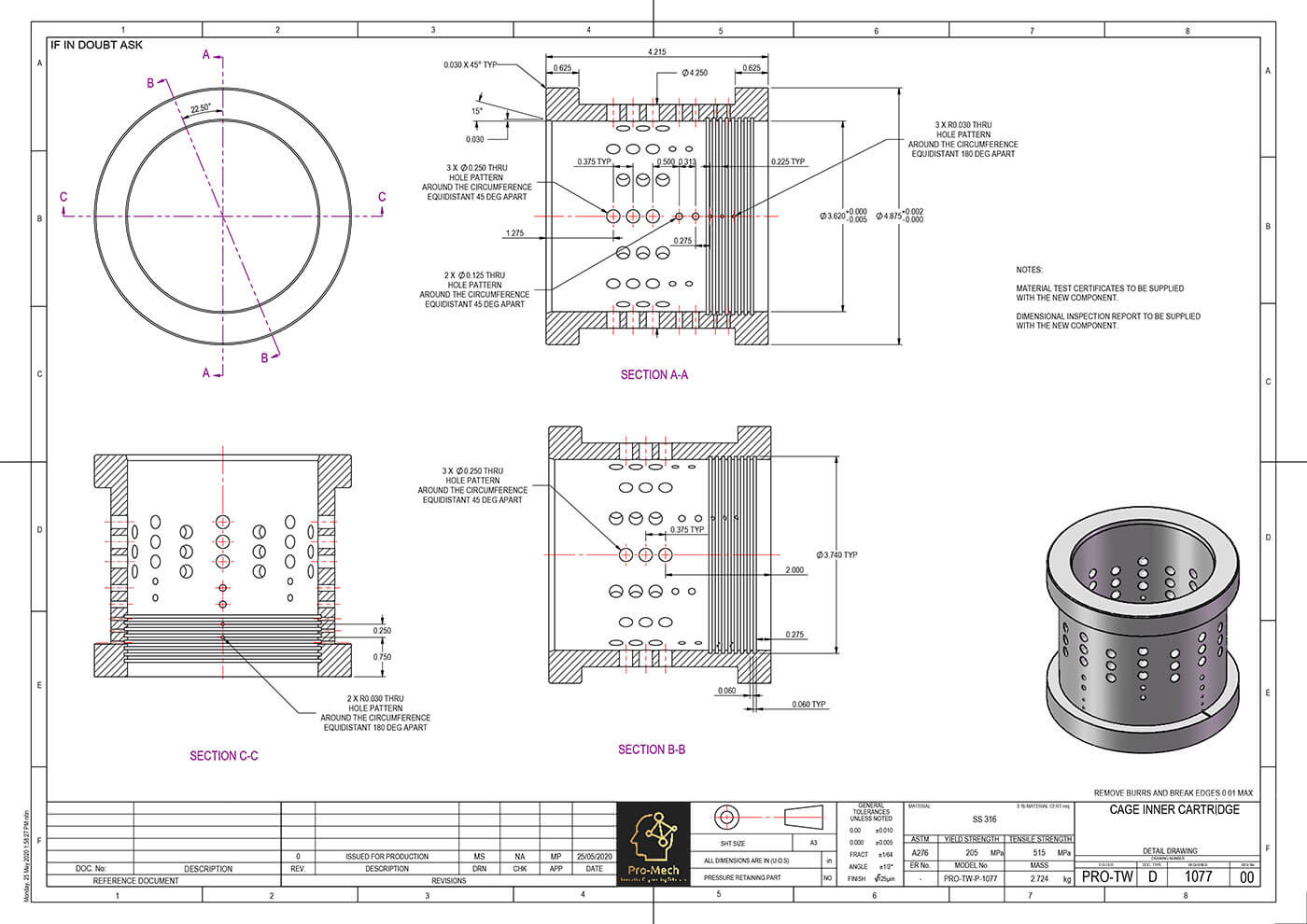

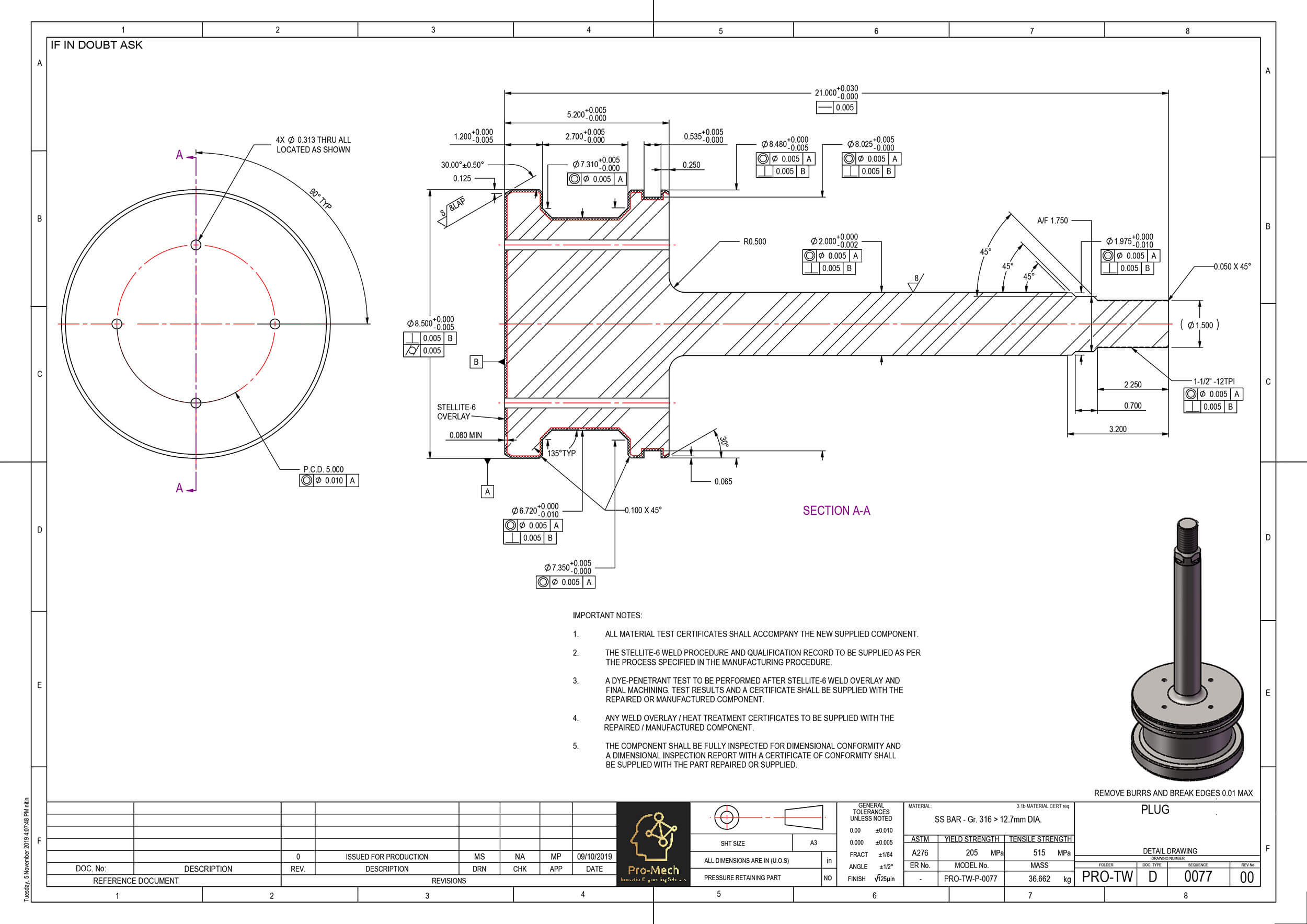

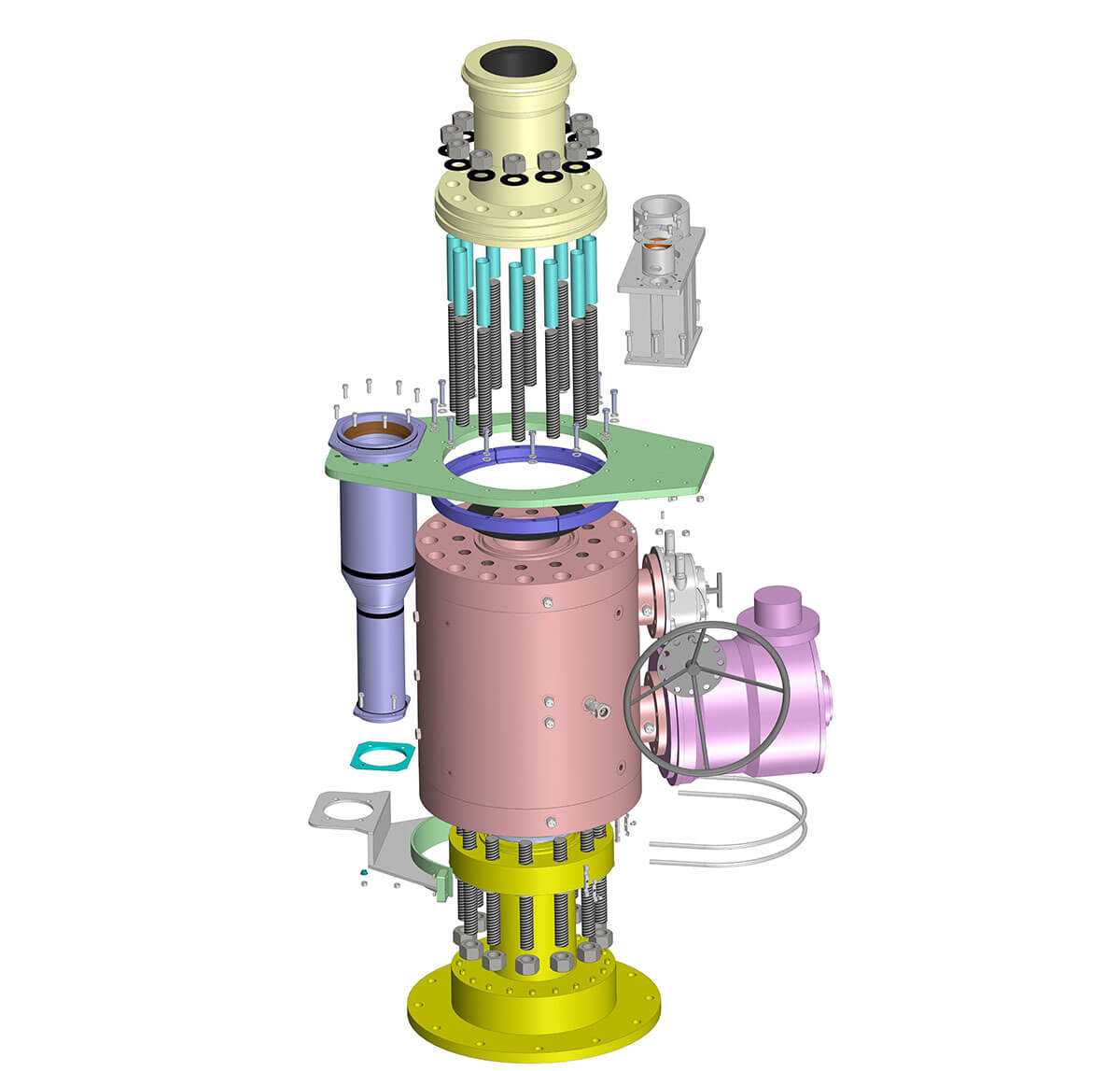

Solidworks 3-D Drawings & Drafting

Using Solidworks, we cater to various drafting requirements, and provide detailed and assembly drawings conforming to GD&T standards.

We also covert 2-D drawings to 3-D drawings, standardise bill of materials to streamline sourcing and manufacturing, thus reducing inventory costs.

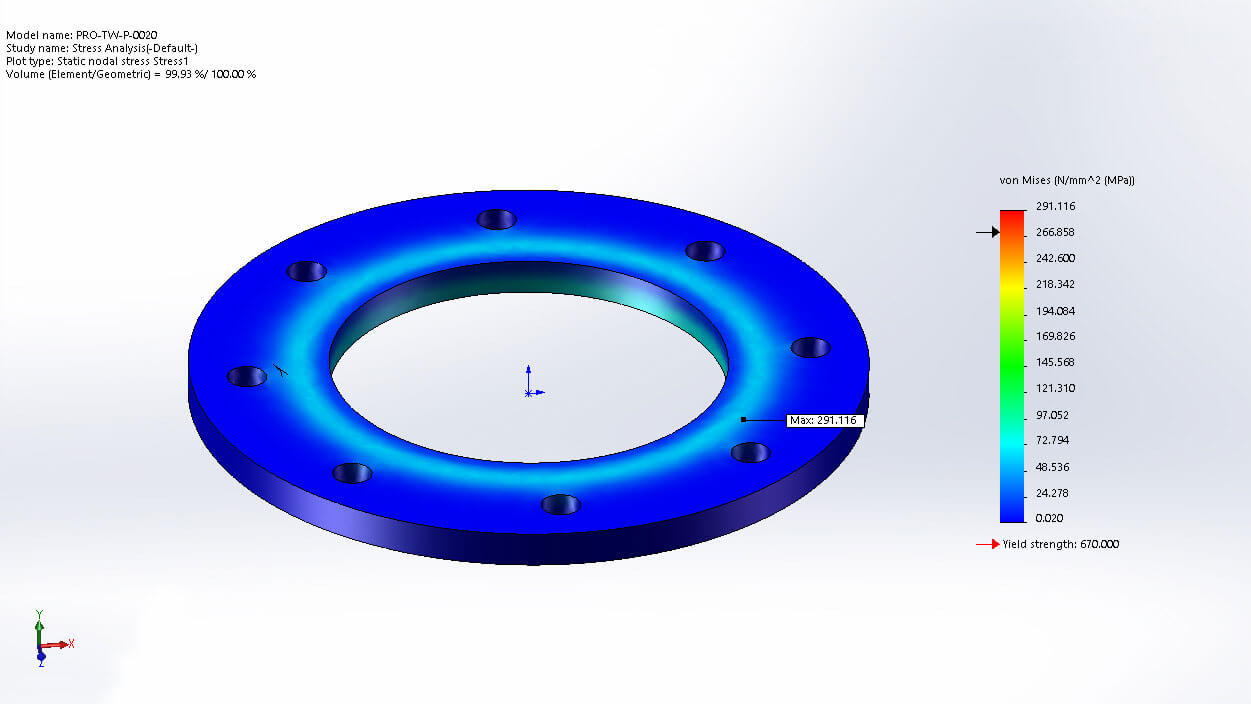

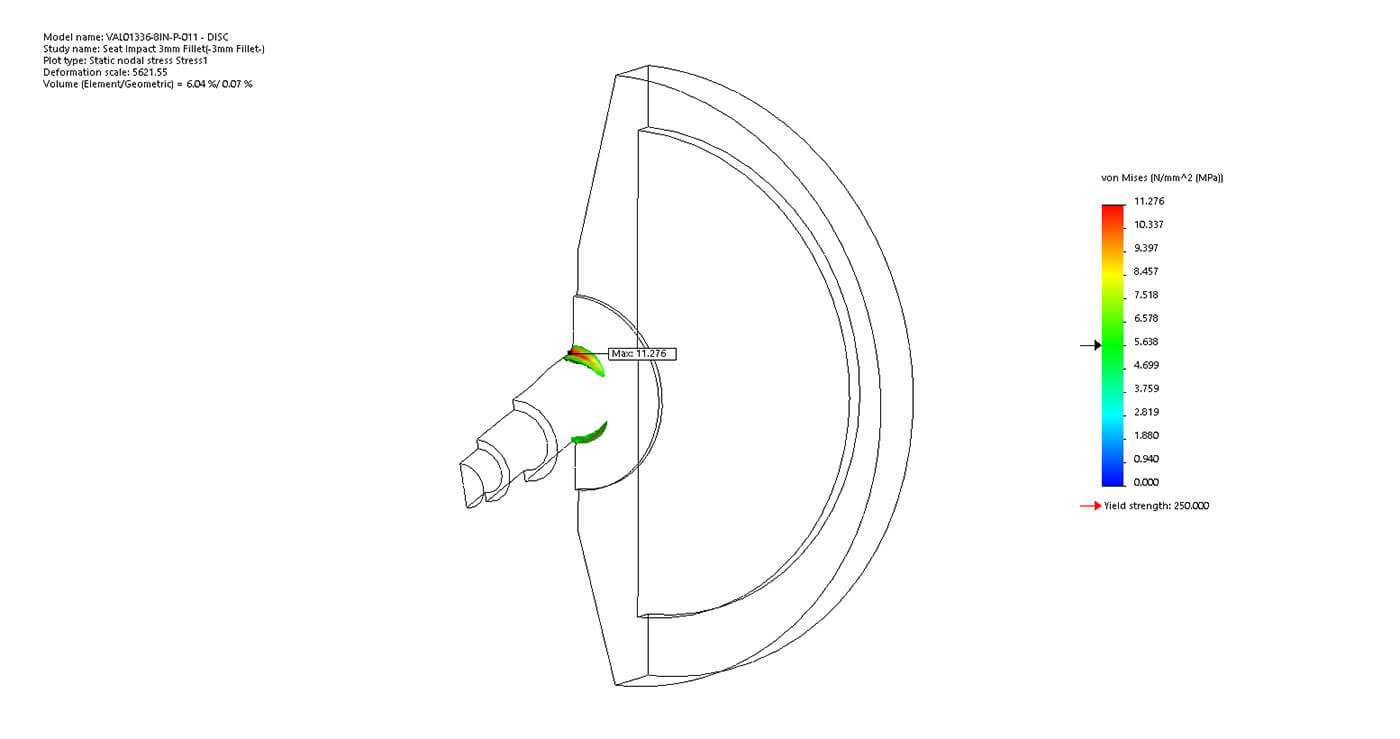

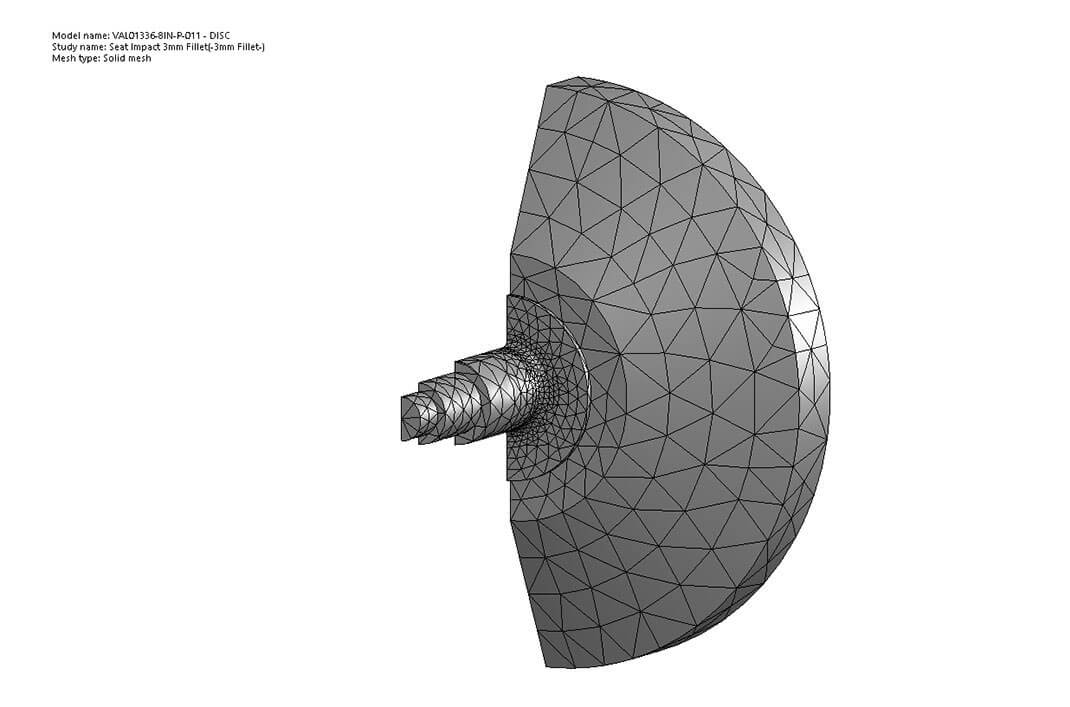

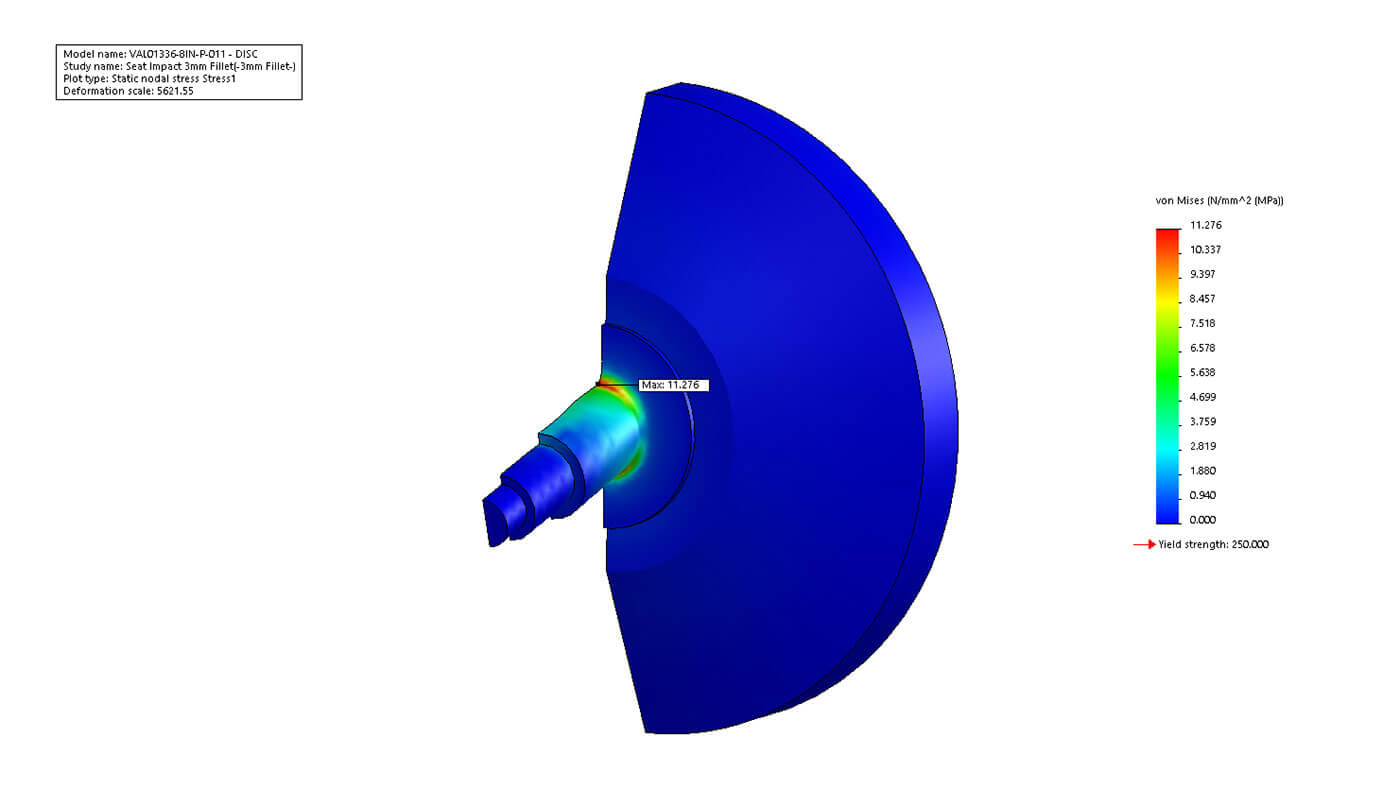

Finite Element Analysis (FEA)

In addition to manual calculations, we use Solidworks Simulation for Finite Element Analysis (FEA) as part of our design process of various components.

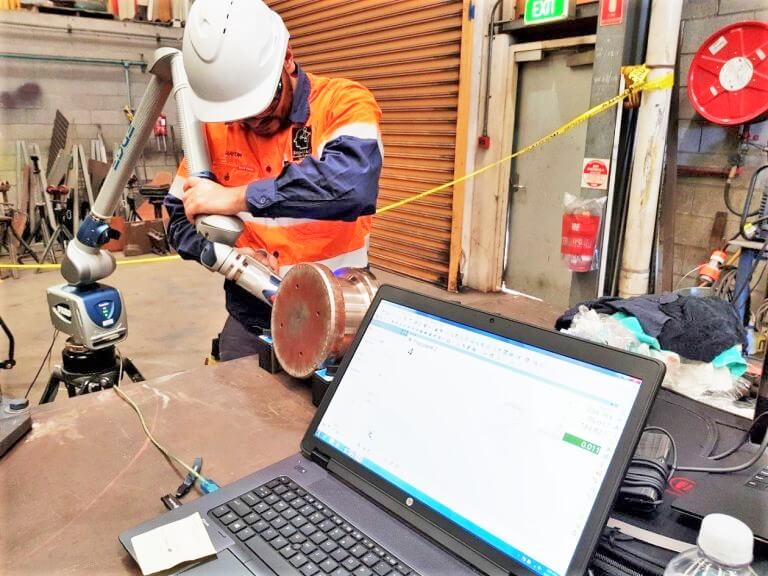

Reverse Engineering

Utilizing a highly accurate 7-Axis FARO CMM arm, we can accurately measure components and prepare drawings for repair or refurbishment of the existing components and, in case of emergency, manufacturing of the replacement parts. This enables the equipment to return to service, when the OEM lead times are high and plant production is suffering.

Reverse engineering is not only beneficial for repairs or manufacturing replacement components, but it also provides an opportunity to find solutions when the existing components or their materials are not suitable for the current process conditions. In such cases, reverse engineering coupled with design and materials engineering provides effective solutions, thereby, improving service life of the components and reducing cost of maintenance.

Installation & Commissioning Plans

We can assist with complex installations and commissioning projects for various equipment types in the plant. We utilize Solidworks to prepare 3-D models, assemblies and drawings to provide a detailed installation plan, thus, eliminating the unknowns during the actual commissioning or installation process.

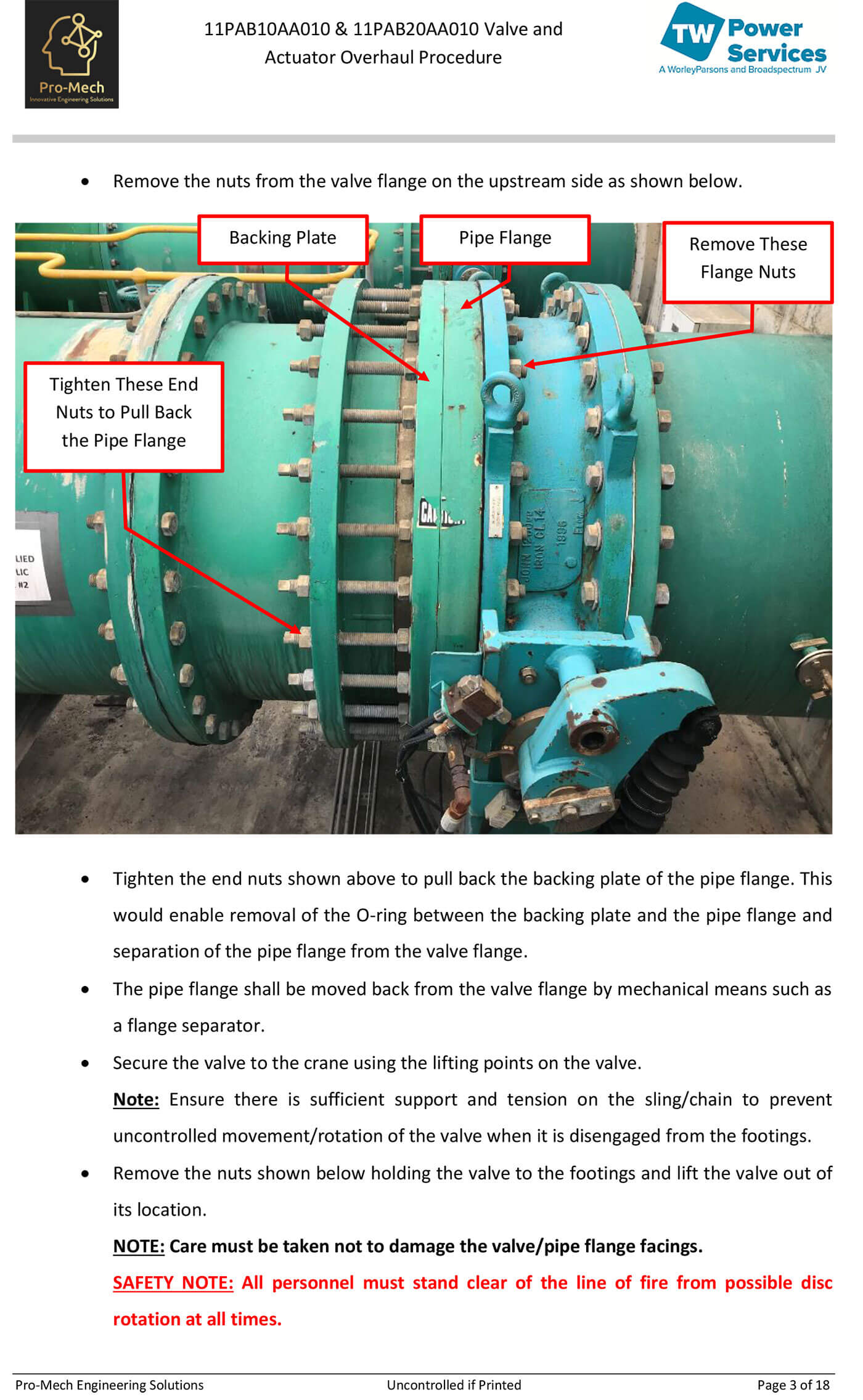

Safe Work Procedures and Inspection & Test Plans

We provide safe work procedures, Inspection and Test Plans, technical information for a thorough and safe execution of any maintenance project.

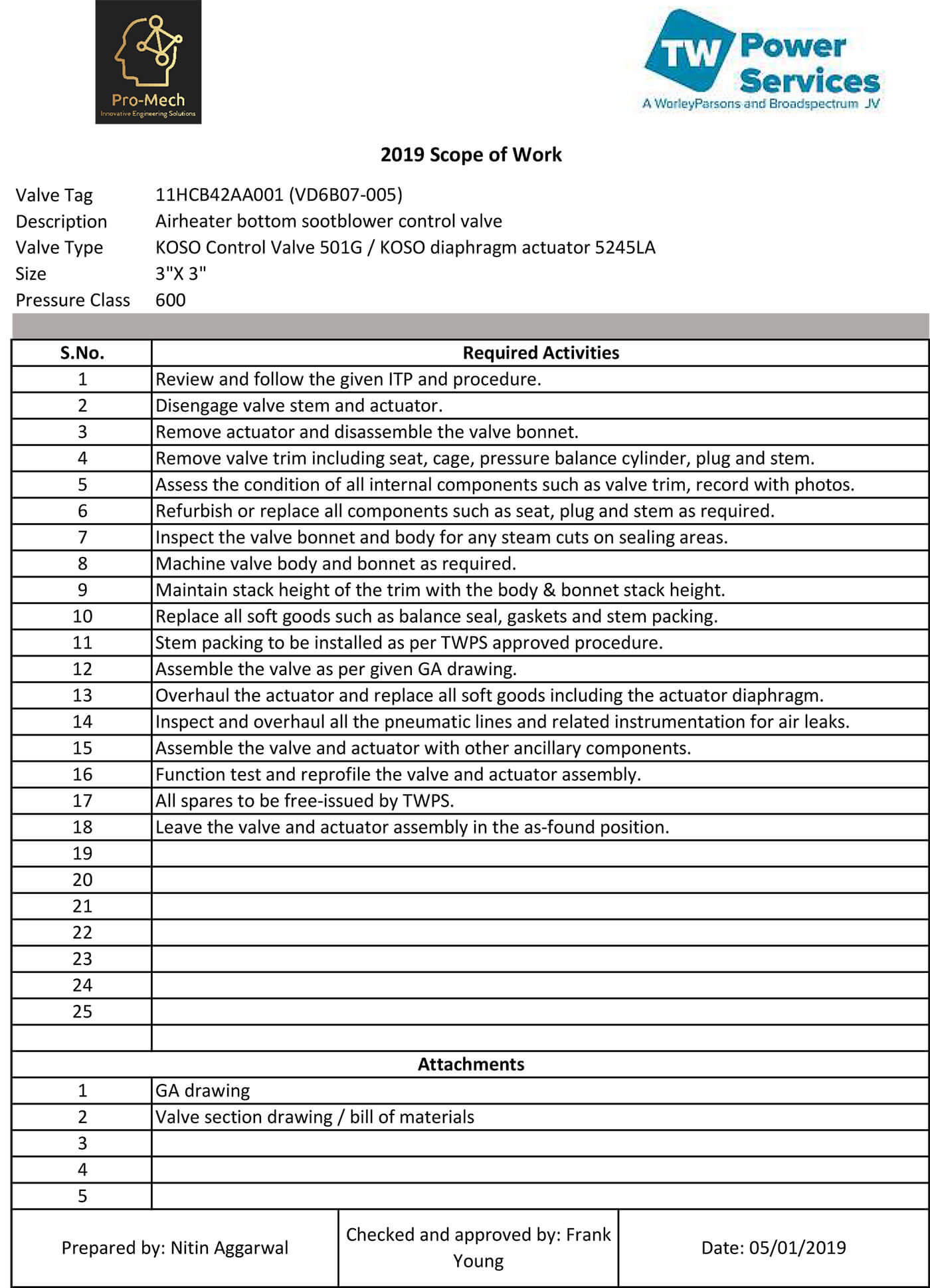

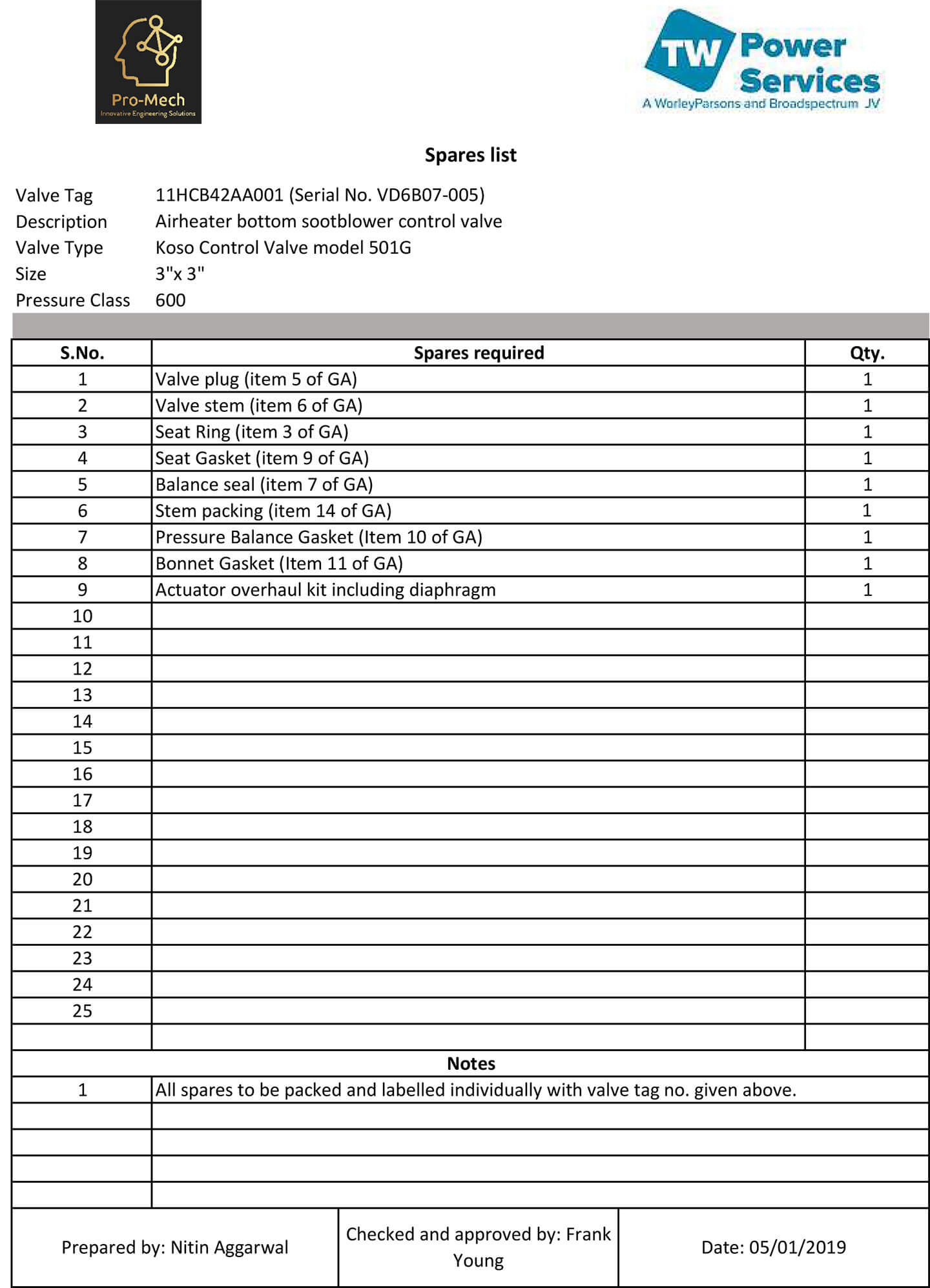

Project Management & Spare Parts Management

With a combined experience of over 15 years, we are well suited to provide Project Management Services for Plant Shutdown & Maintenance projects. Our Project Management services include:

- Detailed Scope Writing.

- Resource Planning.

- Evaluation of contractors and service providers.

- Spare parts management including listing of required spares, sourcing and stocking for easy availability of spares when required.

- Quality Management.

- Procedures and ITPs.

- Execution and Support.

- Onsite and offsite technical Engineering support during plant shutdowns.

- Preparation and Compilation of Datasheets & MDR’s.

Design and Quality Audits, Witness Testing & Factory Acceptance Testing

We provide representation on behalf of our clients for design audits, quality inspections, witness testing & Factory Acceptance testing at the manufacturer’s facilities, local or international, to ensure the equipment conforms to the relevant codes and standards such as ASME, API, AS/NZ etc., or the client specifications.

In-situ Quality Inspections

In-situ repairs on any equipment are often challenging and fraught with issues such as quality assurance.

We can bring confidence in all such activities with our on-site quality inspection services. With our portable CMM arm, we can measure and verify any machining or dimensions within an accuracy of 0.05mm. Our inspections and quality assurance will give you a peace of mind that the work has been completed as per required specifications.

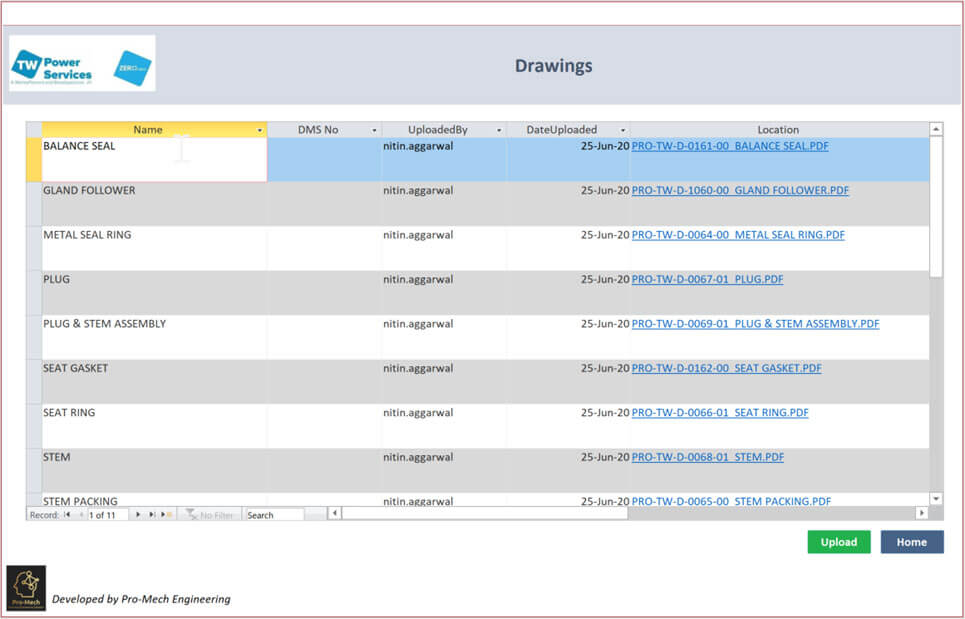

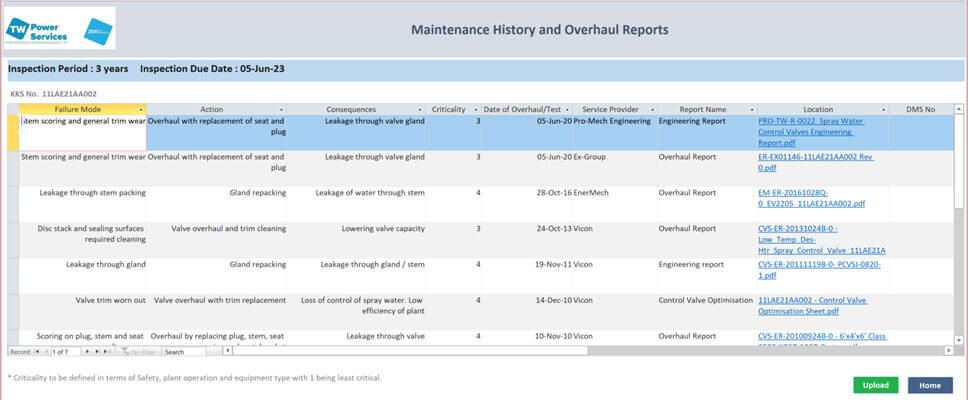

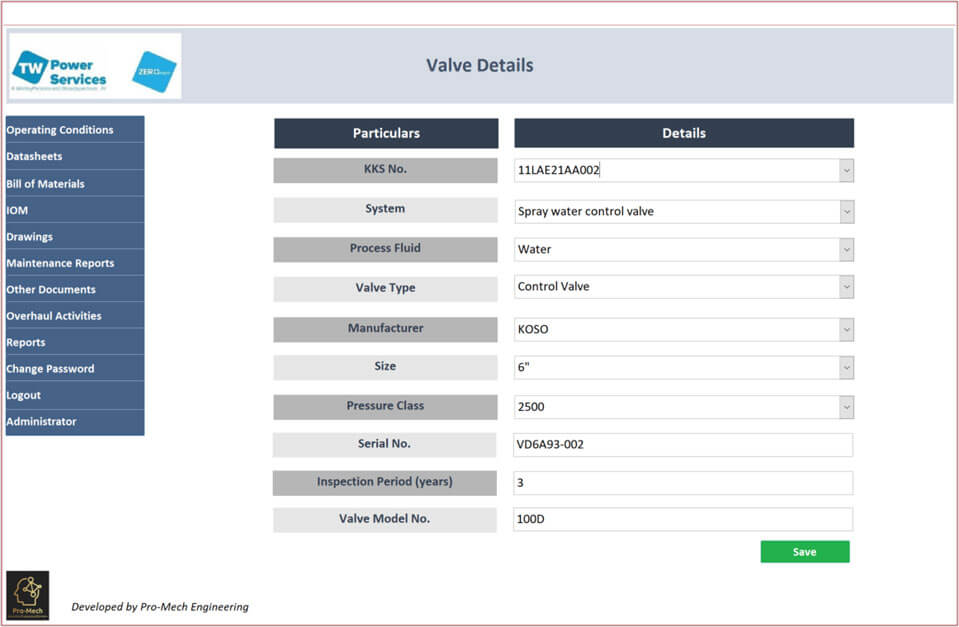

Software Development

For efficient management of information related to equipment and assets, we specialise in developing customised, solution-based software/database with all equipment details, datasheets, drawings, bill of materials, and maintenance histories etc. which enables retrieving information on a click of a button.

The software can be developed as a stand-alone system, hence, easing the storage and retrieval of information from the database.